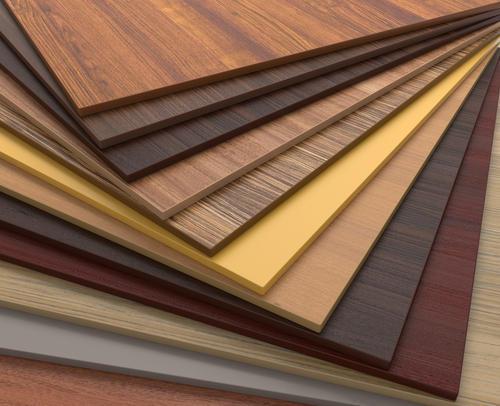

About Decorative Laminates

To manufacture decorative laminates, the brown Kraft paper is soaked in

phenolic resin (phenyl formaldehyde), while the decorative paper and the

protective translucent sheet are soaked in melamine resin. After these papers

become suitably hard, heat and pressure are applied to press and bond them.

The result is a laminated sheet with stylish surface and many amazing

capabilities for different types of installations.

It is worth mentioning that these sheets are designed in two categories that

include high pressure laminates (HPL) and low pressure laminates (LPL).

Though HPL is relatively expensive, it is extremely durable and has longer life

as compared to LPL. Moreover, HPL is apt for both vertical and horizontal

installations, whereas LPL is recommended only for vertical installations in the

low traffic areas. Also, LPL is available in limited varieties.

Supported by an highly experienced team of sound infrastructural base, we are able to serve with best quality of Designer Laminated Plywood Mica. We offer Laminated Plywood Mica is widely valued in various areas. We make sure we use finest raw material coupled with latest techniques in the processing. The plywood micas are provided in a variety of colors and designs in order to match with the speckled needs & different choices of our customers. Our revered clients can purchase offered plywood mica from us within a precise time – frame. reasonable rates.